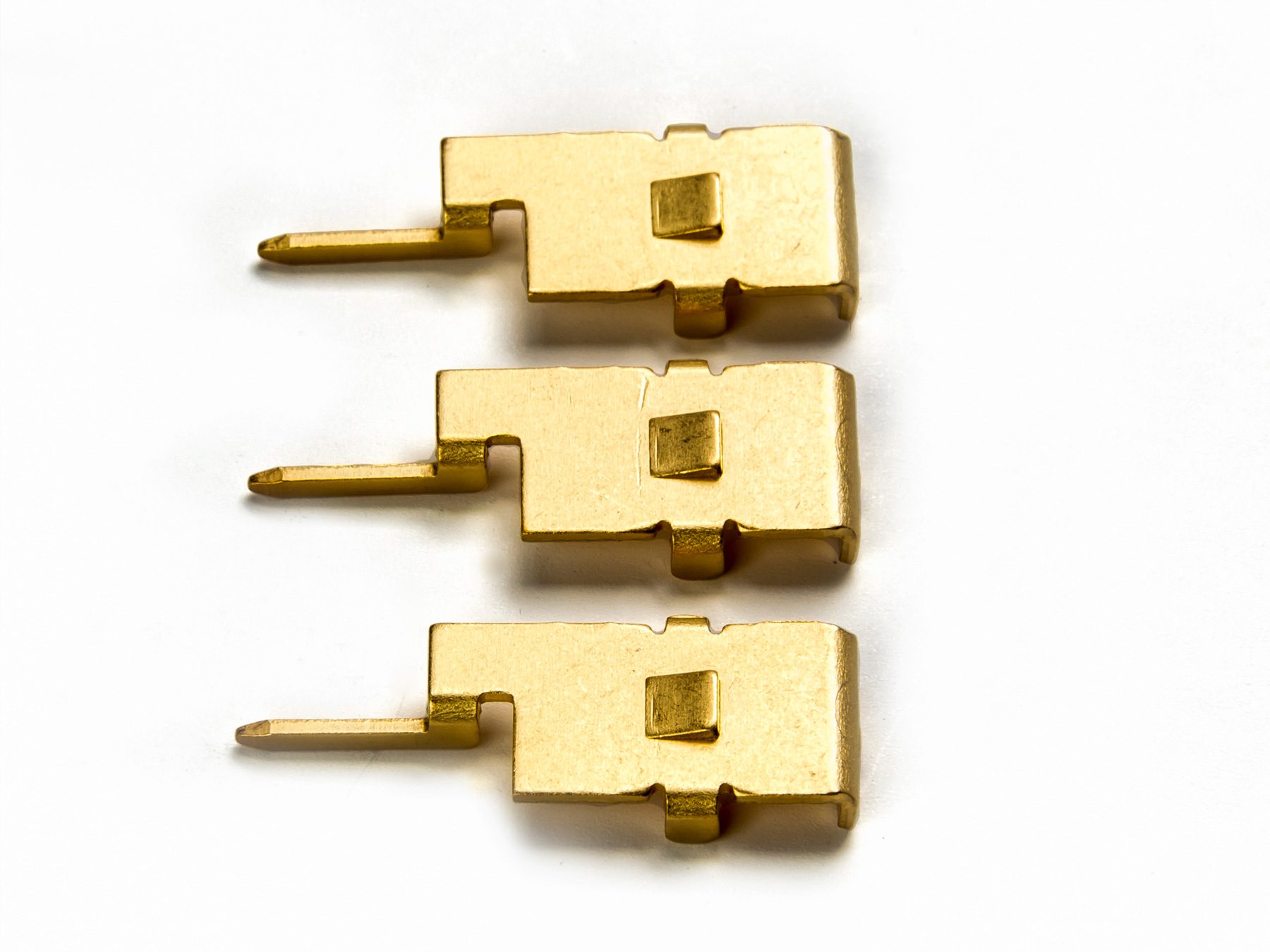

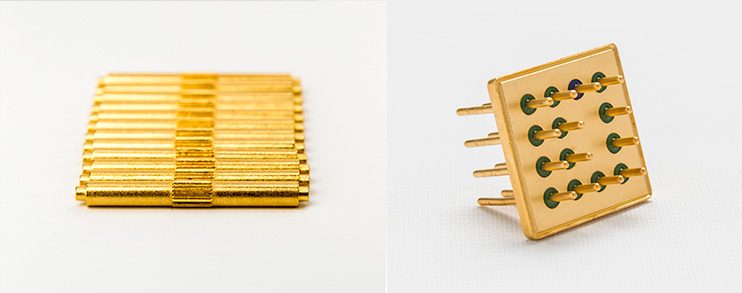

Gold Plating

Williams Plating Company has more than three decades of experience dealing in gold plated engineering solutions for our customers’ needs.

Gold is a highly corrosion resistant finish and has many applications in the electronics industry for solderability, durability, and steady contact resistance over time compared to other finishes less resistant to oxidation.

We can also offer electrolytic nickel, electroless nickel, and copper undercoats depending on our customers’ requirements. These undercoats can improve the final layer of gold’s appearance in addition to assisting with corrosion resistance and level the substrate material in preparation for gold plating. A nickel underplate is also important for copper parts that will be subject to high temperatures serving as a diffusion barrier and preventing intermetallics from weakening the desired characteristics of the gold plating.

We offer rack and barrel plating, have extensive experience in small volume orders, and specialize in complex or unusual gold plating processes tailored to our customer’s specific needs.

WPC sources only Conflict Free gold from smelters certified by the Responsible Minerals Initiative (RMI). Our completed Conflict Minerals Reporting Template and any additional quality information can be found on our Quality Controls page, or can be directly downloaded here.

Gold plating services offered:

Soft Gold – Type III Code A Soft Gold

This 99.9% minimum gold deposit is plated without any alloying metals and produces a very pure, soft deposit excellent for high temperature applications such as wire bonding and soldering. The high purity maintains the elemental properties of gold for industrial applications including high melting point which will inhibit the gold from diffusing into a substrate metal and imparting metallic impurities. Metallic impurities in the deposit can lead to solderability issues in addition to increased electrical resistance and susceptibility to corrosion.

Hard Gold – Type I/II Code C Hard Gold

This gold is 99.0-99.7% pure, containing small amounts of nickel added to increase the hardness of the deposit. This finish is more wear resistant than the soft gold and is favored in most general purpose applications.

Gold with 15-20% Silver alloy

Our one-of-a-kind silver alloyed gold plating line meets the specific needs of our customers to have a durable and corrosion resistant finish for electrical contacts. We can control the silver content of this gold plating with current density manipulation to produce the desired deposit.

When considering gold plating for your product, please determine and convey:

- Type, code and class for ASTM B488

- Any specific gold alloying requirements

- Type and nature of the substrate base metal (i.e., high strength steel will tell us that it is susceptible to hydrogen embrittlement and may require post-plate baking)

- Plating thickness range and possibly where is the most important surface location of desired thickness

- Significant surfaces

- Required undercoats or strike layers

- Any post-plate baking requirement

- Any specific testing required to the plated deposit

- Please convey if the part must be rack or barrel plated if you have already determined this

Specifications for gold plating:

- AMS 2422

- ASTM B488

- MIL-DTL-45204

- MIL-G-45204