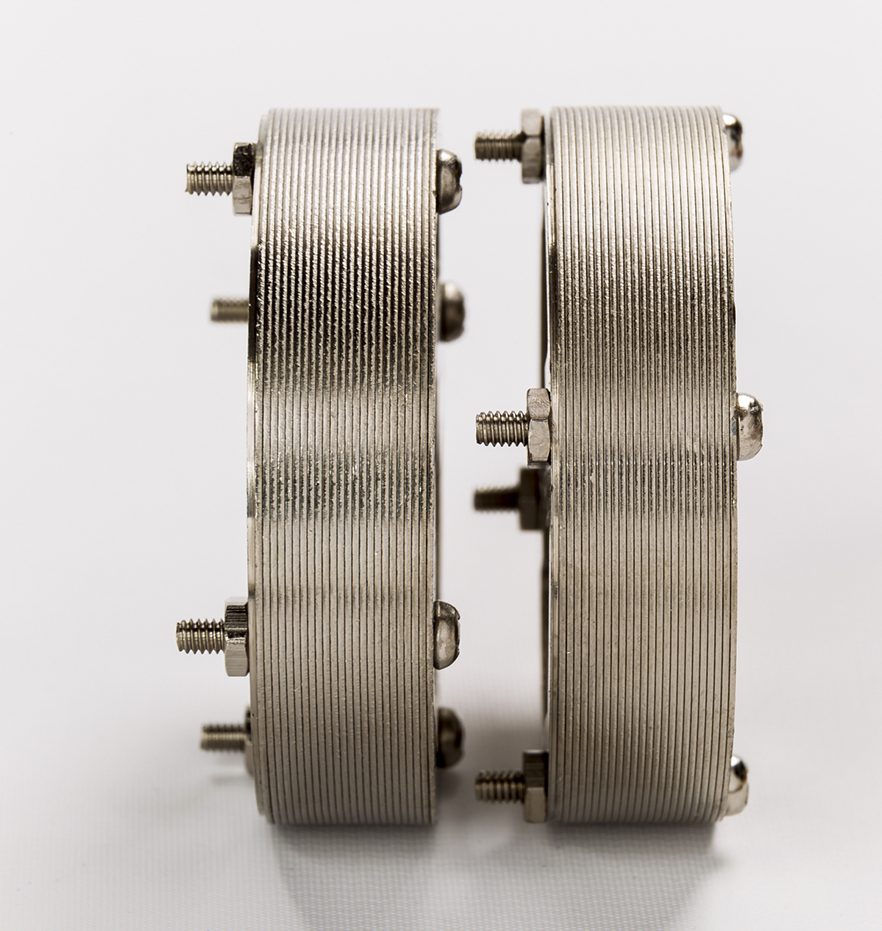

Electroless Nickel Plating

WPC offers electroless nickel (EN) plating for functional and industrial products specializing in electrical components for relays, solenoids and switches, and industrial coating for high value component and machining equipment. EN plating is an excellent option for parts needing nickel plating, but requiring higher corrosion resistance. EN can provide greater coverage than electroplated (electrolytic) nickel in parts with difficult geometry such as one-way holes or recesses.

WPC can offer EN plating as a medium phosphorous alloy bath, which provides an excellent general industrial electrical component coating. Medium phosphorous EN plating is 5 to 9% P providing corrosion and wear resistance, lubricity, and excellent coverage. WPC is fully capable and knowledgeable of masking and selective EN plating.

Looking for a nickel plating with more solderability properties? WPC offers electrolytic nickel plating that may better suit your application.

When considering electroless nickel plating for your product, please determine and convey:

- Type and classification for ASTM B733-04

- Class for AMS 2404F

- Type and nature of the substrate base metal (i.e., high strength steel will tell us that it is susceptible to hydrogen embrittlement and may require post-plate baking)

- Plating thickness range and possibly where is the most important surface location of desired thickness

- Significant surfaces

- Required specific surface preparation such as vibratory or glass bead blasting

- Required undercoats or strike layers

- Any post-plate baking requirement

- Any specific testing required to the plated deposit

- Please convey if the part must be rack or barrel plated if you have already determined this

Specifications for Electroless Nickel Plating:

- AMS 2404F

- ASTM B733-04

- MIL-C-26074